Low voltage switchgear

I. The importance of low voltage switchgear in electrical automation

- Ensure the security of the power system

One of the primary functions of low voltage switchgear is to protect power systems and equipment from hazards such as overloads and short circuits. By integrating various protective devices like circuit breakers, fuses, and relays, these cabinets can swiftly detect and isolate faults, preventing their escalation and ensuring safe system operation.

- Improve the reliability of power system

Low voltage switchgear ensures the normal operation of each power equipment by rationally distributing and controlling electric energy. They can flexibly distribute and manage electric energy according to actual demand, ensure the stability and reliability of power supply, and reduce the downtime time caused by power failure.

- Improve the level of electrical automation

Low voltage switchgear integrates modern control and monitoring technologies such as PLC (Programmable Logic Controller), HMI (Human-Machine Interface), and SCADA (Supervisory Control and Data Acquisition System), significantly enhancing the automation and intelligence of power systems. Through these technologies, low voltage switchgear enables remote monitoring, real-time data collection, and intelligent control, thereby improving system operational efficiency and management standards.

- Optimize power quality

Through the configuration of reactive power compensation devices and filter devices, low voltage switchgear can effectively improve power quality, reduce harmonic content, reduce power grid loss, and optimize the power environment. High-quality power supply can extend the service life of equipment and improve production efficiency.

- Meet the needs of modern industry

In modern industrial environments, power demands are complex and ever-changing. Low voltage switchgear provides a flexible solution that can be customized and configured according to different industrial needs. Whether it is a high-load industrial production line or precision instrumentation, low voltage switchgear can provide a stable and reliable power supply.

- Simplify power system management

Low voltage switchgear simplifies the installation and maintenance of power systems through modular design and standardized production. Standardized design makes it easier and faster to expand and upgrade power systems, while reducing system maintenance costs and management difficulties.

- Support for sustainable development

Modern low voltage switchgear pays attention to environmental protection and energy saving in the design and manufacturing process. Through efficient power management system and energy-saving components, it reduces energy consumption and environmental pollution, and supports enterprises to achieve the goal of sustainable development.

- Provide comprehensive solutions

Low voltage switchgear is not just a simple power distribution device, but a comprehensive power solution. They can integrate protection, measurement, control and communication functions to provide users with one-stop power system solutions that meet the needs of different application scenarios.

- Comply with national standards and specifications

The design, manufacture and use of low voltage switchgear comply with relevant national standards and specifications to ensure safety and reliability in a variety of application scenarios. Standardized products not only enhance user trust, but also make the products competitive in the international market.

As demonstrated by the detailed analysis above, low voltage switchgear plays a comprehensive role in electrical automation. These devices are indispensable for ensuring safety, enhancing reliability, optimizing power quality, and supporting intelligent management systems. As core components of electrical automation systems, the selection and application of low voltage switchgear are critical to maintaining overall system performance and stability.

II. Basic overview of low voltage switchgear

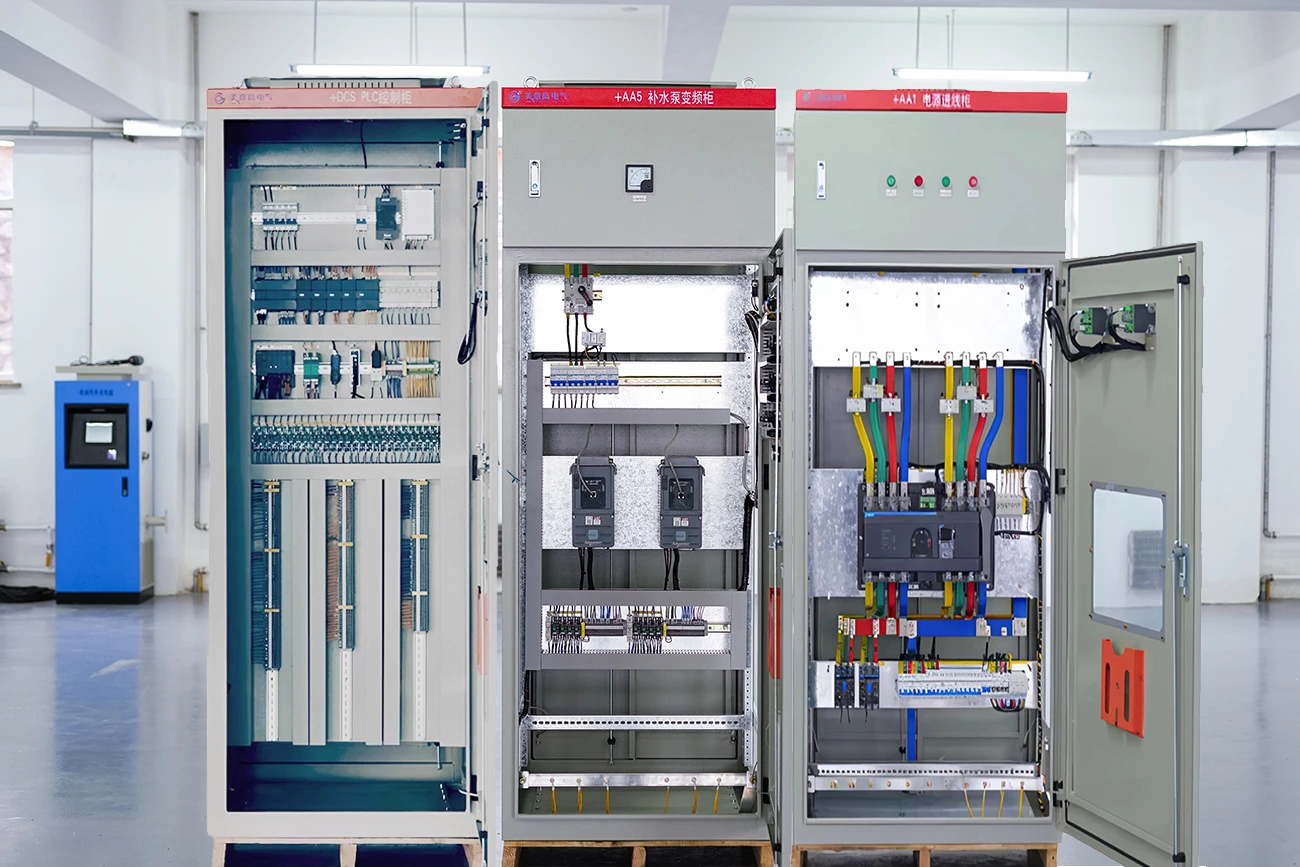

1. Definition of low voltage switchgear

A low voltage switchgear cabinet is an electrical device used in power systems for power distribution, control, and protection. Specifically, it is an integrated unit containing multiple low-voltage electrical components (such as circuit breakers, fuses, contactors, relays, and measuring instruments) housed within a sealed or semi-sealed metal enclosure. These cabinets are typically employed in power systems operating at alternating current (AC) voltages up to 1000 volts and direct current (DC) voltages up to 1500 volts.

2. Main functions of low voltage switchgear

-

Power distribution

A major function of low voltage switchgear is power distribution. It distributes power from one or more sources to multiple loads, ensuring a stable supply of electricity to each electrical device. Through proper distribution, the efficiency and reliability of the system can be improved.

-

Fault protection

Low voltage switchgear integrates various protection devices, such as circuit breakers, fuses, and leakage protectors. When faults such as overload, short circuit, or leakage occur in the power system, these protection devices will respond quickly to cut off the power supply, so as to protect circuits and equipment from damage and ensure personnel safety.

-

Control and monitoring

Low voltage switchgear cabinets are typically equipped with control devices (such as PLCs and control relays) and monitoring instruments (including ammeters, voltmeters, and power meters). These components enable real-time monitoring and control of power systems, ensuring reliable and safe operation. For example, monitoring instruments allow real-time tracking of system status, while control devices facilitate the execution of corresponding operations.

-

Isolation and switching

The isolating switches and transfer switches in low voltage switchgear enable circuit isolation and load switching. This is particularly crucial during maintenance and repair operations, ensuring operator safety. Furthermore, the transfer switches facilitate seamless switching between primary and backup power supplies, guaranteeing uninterrupted power supply for critical loads.

-

Electric energy metering

Low voltage switchgear is usually equipped with electric energy metering device, which can accurately measure the use of electric energy. This is of great significance for power management and energy saving and emission reduction, and can help users understand the consumption of electric energy, so as to take energy-saving measures.

-

Power quality management

Through the integrated power quality monitoring equipment, the low voltage switchgear can monitor and manage the voltage, frequency, harmonic and other parameters of the power system to ensure that the power quality meets the requirements and avoid the impact of power quality problems on equipment and system.

-

Communication and remote control

Modern low voltage switchgear is usually equipped with communication and remote control functions. Through the integrated communication module, it can communicate with the upper computer system and support remote monitoring and operation. This provides the foundation for smart grid and automated management.

-

Interlocking and interlocking

Interlock and interlock devices in low voltage switchgear can prevent misoperation and improve the safety of operation. For example, certain switches cannot be closed until another switch is disconnected, ensuring the correctness and safety of operation.

-

Environmental monitoring

Some low voltage switchgear is equipped with environmental monitoring devices, which can monitor the temperature, humidity and other environmental parameters inside the cabinet, give early warning of abnormal conditions, and prevent environmental factors from affecting the operation of equipment.

-

User management

Through the function of permission management and operation record, the low voltage switchgear can realize the operation management of users, prevent unauthorized operation, improve the security and management level of the system.

To sum up, low voltage switchgear plays a vital role in the power system. Through the integration and application of various functions, it not only improves the security and reliability of the system, but also supports the intelligent and automated management of the power system

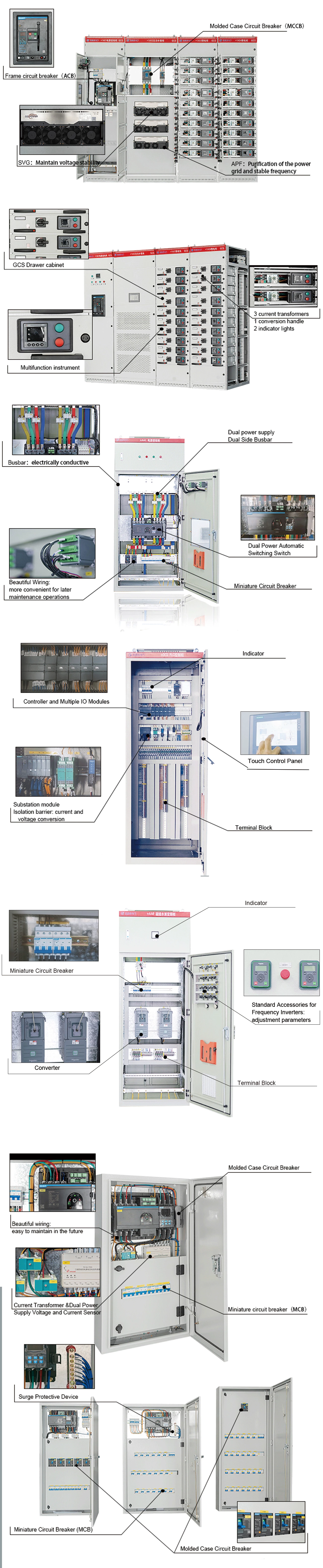

3.The basic components of low voltage switchgear

-

Bus system

Main bus: used for power transmission and distribution, usually made of copper or aluminum, with good electrical conductivity and mechanical strength.

Branch bus: connects the main bus to each functional unit and transmits power to the load.

-

Circuit breakers

Air circuit breaker (ACB): used for high current protection and control, with large breaking capacity.

Shaped case circuit breaker (MCCB): suitable for medium current protection and control, widely used in branch circuits.

Micro circuit breaker (MCB): commonly used for protection of small current, mainly used in terminal distribution.

-

Isolation switch

Used for circuit isolation to ensure that the circuit is completely disconnected during maintenance and repair to ensure the safety of operators.

-

Fuses

Used for overcurrent protection. When the current exceeds a certain value, the fuse melts and cuts off the circuit to protect equipment and cables.

-

Contactors

Switching operation for motor and other loads, with remote control function.

-

Relays

Used for various protection and control functions, including overload protection, short circuit protection, leakage protection, etc.

-

Current transformers (CT)

Used for current measurement and protection, reducing high currents to measurable range, provided for use by instruments and protection devices.

-

Voltage transformers (PT)

Used for voltage measurement, reducing high voltage to measurable range, for use by meters and protection devices.

-

Control unit

PLC (programmable logic controller): used for complex control logic, to achieve automatic control.

Control relay: used for simple logic control and signal transmission.

-

Monitoring and instrumentation

Current and voltage meters: used to monitor current and voltage in real time.

Power table, power factor table: used to monitor power parameters.

Multi-functional power meter: integrates multiple measurement functions to provide comprehensive power data.

-

Protective devices

Residual current protector: used to detect residual current and cut off the circuit quickly.

Overload protector: used to prevent motor and cable overload.

Short circuit protector: used to respond quickly to short circuit faults.

-

Communication module

It is used to realize communication with the host computer system and support remote monitoring and control. Common communication protocols include Modbus, Profibus, Ethernet, etc.

-

Grounding system

Used to ensure the safe grounding of electrical systems and prevent leakage and electric shock.

-

Cabinet and enclosure

Cabinet structure: usually made of steel plate, with good mechanical strength and protection grade.

Doors and panels: Provide access for operation and maintenance with observation Windows and indicator lights.

-

Cooling and ventilation

Used for heat dissipation to ensure that the internal temperature of the switchgear is within the safe range, common natural ventilation and forced ventilation systems.

-

Assistive devices

Lighting: Used to provide internal lighting for easy operation and maintenance.

Heater: used to prevent moisture condensation, often used in humid environment.

Through the integration and collaboration of these basic components, the low voltage switchgear can realize the distribution, control, protection and monitoring of electric energy to ensure the efficient, safe and reliable operation of the power system.

III. Basic overview of low voltage switchgear

| Cabinet type | introduce | frequency | rated voltage | rated current | major function | application area | Characteristic analysis |

|---|---|---|---|---|---|---|---|

| GGD mould | Fixed low voltage switchgear | 50HZ / 60HZ | 380V | 3150A | Power distribution, circuit protection, circuit control, power monitoring, fault indication, electrical isolation, automation function, safety protection, flexible expansion, environmental adaptability | Industrial and mining enterprises, civil buildings, public facilities, power systems, etc | Modular design, high reliability, easy to operate, simple maintenance, strong adaptability, good ventilation and heat dissipation performance |

| GCS mould | Drawer-type low voltage switchgear | 50HZ / 60HZ | 660V | 4000A | Power plants, substations, industrial enterprises, infrastructure, etc | Highly modular design, drawer structure, easy to maintain and expand, high flexibility, high reliability, high protection level | |

| GCK mould | Drawer-type low voltage switchgear | 50HZ / 60HZ | 380V | 3150A | Power distribution, circuit protection, circuit control, power monitoring, fault indication, electrical isolation, automation function, safety protection, flexible expansion | Industrial and civil power distribution systems, especially for places that require frequent operation or maintenance | The drawer design is easy to maintain and replace, the modular design is simple wiring, high safety, high protection level |

| MNS mould | Modular low voltage switchgear | 50HZ / 60HZ | 660V | 4000A | Power distribution, circuit protection, circuit control, power monitoring, fault indication, electrical isolation, automation function, safety protection, flexible expansion, environmental adaptability | Power plants, substations, industrial enterprises, infrastructure, etc | Highly modular design, high degree of standardization, strong flexibility, easy operation and maintenance, high protection level, high reliability |

| XL-21 model | Power distribution cabinet | 50HZ / 60HZ | 380V | 630A | Power distribution, circuit protection, power monitoring, fault indication, electrical isolation | Industrial and mining enterprises, civil buildings, power systems, etc | Simple structure, low cost, easy to install and maintain, suitable for small power distribution system, low protection level, suitable for indoor environment |

IV. Design and selection of low-voltage switchgear

1. Factors to consider in design

- Electrical parameters:

Rated voltage and current: Ensure that the switchgear can handle the voltage and current required by the system.

Short circuit current capacity: the maximum short circuit current that can be tolerated by the system.

Insulation class: select appropriate insulation materials and structures according to system voltage.

- Functional requirement :

Power distribution function: meet the needs of power distribution and power management.

Protection function: overload, short circuit, leakage and other protection functions.

Control function: support the control and monitoring of electrical equipment.

Automation function: can be integrated with the automation system to realize remote control and monitoring.

- Ambient condition :

Temperature and humidity: The design shall consider the temperature and humidity range of the installation environment.

Protection class: Select the appropriate protection class (e.g. IP class) according to the installation location (indoor or outdoor).

Seismic performance: In the earthquake-prone areas, seismic design should be considered.

- Architectural design :

Modular design: easy to expand and maintain.

Cabling mode: reasonable design of cabling, ensure that the lines are clear and neat for maintenance.

Ventilation and heat dissipation: ensure the heat dissipation of equipment in the cabinet to avoid overheating.

Size and weight: Suitable for field installation, easy to transport and install.

- Safety :

Operational safety: The design shall ensure the safety of operators and maintenance personnel to prevent misoperation.

Fire performance: use fire-resistant materials to prevent electrical fire.

Grounding and shielding: Ensure good grounding and electromagnetic shielding to prevent electric shock and electromagnetic interference.

- Economical efficiency :

Cost control: under the premise of meeting the functional requirements, try to control the design and manufacturing costs.

Maintenance cost: consider the convenience of maintenance in design to reduce long-term maintenance cost.

- Standards and specifications:

Comply with national and industry standards: such as IEC, GB, UL and other standards to ensure that the design and manufacture of switchgear meet the specifications.

Meet customer requirements: meet customer's special needs and specifications.

- Extendibility :

Future expansion: The design should consider the possibility of future system expansion, and reserve corresponding space and interface.

- Aesthetics and signage:

Aesthetic design: conform to industrial aesthetics, easy to identify.

Clear identification: The identification of equipment and lines should be clear and easy for operators and maintenance personnel to identify

2. Selection criteria and specifications

- National and international standards:

IEC standards: Most countries adopt international Electrotechnical Commission (IEC) standards, such as the IEC 61439 series standards, which cover the design, manufacture, test and use of low-voltage switchgear.

GB standard: China's national standards, such as GB/T 7251 series standards, are basically in line with IEC standards, but there are some specific requirements.

UL standards: Widely used in North America, such as UL 508A standard, which is suitable for industrial control panels and low-voltage switchgear.

- Technical parameter:

Rated voltage (Un): Select the appropriate rated voltage according to the system voltage level, generally 400V,690V, etc.

Rated current (In): Select the appropriate rated current according to the load size to ensure that the switchgear can withstand the maximum load current.

Short circuit current capacity (Icc): Must be able to withstand the maximum short circuit current that may occur in the system, usually required at 20kA, 50kA or higher.

- Function configuration:

Circuit breakers (MCCB, ACB): Select the appropriate type and specification of circuit breaker to ensure that it has overload, short circuit and leakage protection functions.

Contactors and relays: Select appropriate contactors and relays according to control requirements to ensure reliable control.

Measurement and display device: configure voltage, current, power and other measuring instruments to facilitate the monitoring of system operating status.

Automation and communication modules: If you need to integrate with the automation system, you need to configure the corresponding communication modules, such as Modbus, Profibus, etc.

- Environmental suitability:

Protection class (IP class): the protection class is determined according to the installation environment, such as IP31, IP54, etc., to ensure dustproof and waterproof.

Resistant to temperature and humidity: Select materials and equipment that are adapted to the temperature and humidity range of the installation environment.

Seismic performance: in earthquake-prone areas, choose the switchgear with seismic design.

- Architectural design:

Modular design: easy to expand and maintain.

Ventilation and heat dissipation: Ensure the heat dissipation requirements of the equipment during operation to avoid overheating.

Size and layout: Design reasonable size and layout according to the installation space for easy on-site installation.

- Safety:

Operational safety: The design shall ensure the safety of operators and maintenance personnel, prevent misoperation, and provide necessary interlock devices.

Fire performance: choose fire-resistant materials, and arrange necessary fire alarm and fire fighting devices.

Grounding and shielding: Ensure good grounding and electromagnetic shielding to prevent electric shock and electromagnetic interference.

- Economical efficiency:

Cost control: control the design and manufacturing costs on the premise of meeting the functional requirements.Maintenance cost: choose easy to maintain structure and equipment, reduce long-term maintenance costs.

- Meet customer and project needs::

Customized requirements: customized design according to the special needs of customers and specific projects.Certification and compliance: Ensure that the switchgear is certified and compliant with relevant regulatory requirements.

V. Future development trends

- Direction of technological innovation

Low-voltage switchgear presents multiple noteworthy directions in technological innovation and future development trends. These innovations and trends not only enhance the performance and reliability of switchgear but also better meet the demands of intelligentization and digitalization. The following outlines key technological innovation directions and future development trends:

- Intelligent and digital

Intelligent monitoring and control: integrate intelligent sensors and controllers to realize real-time monitoring and control of current, voltage, temperature and other parameters, and have fault diagnosis and early warning function.

IoT integration: Through the Internet of Things technology, the low-voltage switchgear is connected to the cloud platform to realize remote monitoring, data analysis and management, and improve the operation and maintenance efficiency.

- building block design :

Modular and standardized units: Modular design is adopted to facilitate rapid assembly, expansion and maintenance, reduce downtime, and improve system flexibility and scalability.

Plug and play modules: Designed as plug and play modules to facilitate replacement and upgrade, while reducing maintenance time and cost.

- Green environmental protection and energy saving:

Use of environmentally friendly materials: Select environmentally friendly materials and processes to reduce the impact on the environment.

Energy efficiency management: integrate energy efficiency management system, optimize power use, reduce energy waste.

- High reliability and security

Advanced protection technology: adopt more advanced protection technology, such as electronic protection device, intelligent circuit breaker, etc., to improve the protection performance of the system.

Anti-interference design: improve the anti-electromagnetic interference (EMI) capability to ensure stable operation in complex electromagnetic environment.

- Human machine interface (HMI) optimization

Friendly human-machine interface: adopt modern human-machine interface such as touch screen and graphical interface, simple operation and intuitive information display.

Remote operation and maintenance: Support remote operation and maintenance to reduce the risk and difficulty of field operation.

- High density and miniaturization:

Compact design: Through optimization of internal structure and component layout, higher integration is achieved and footprint space is reduced.

Miniaturized components: Use miniaturized and lightweight components to improve the overall efficiency and performance of the equipment.

- High reliability and long life

High quality components: Select high quality, long life key components to extend the service life of equipment.

Reliable cooling system: Design efficient cooling system to ensure stable operation of equipment under high load.

- Data analysis and predictive maintenance

Big data analysis: Provide data support for equipment operation status and performance through data collection and analysis, and help predictive maintenance and fault prevention.

Machine learning and artificial intelligence: Apply machine learning and artificial intelligence technology to realize intelligent analysis and optimization of equipment status.

- Customized solutions

Personalized design: provide customized low-voltage switchgear solutions according to the special needs of different industries and customers.

Industry-specific functions: Develop specific functions and features for specific industries (such as medical, communication, manufacturing, etc.).

- Internationalization and standardization

Comply with international standards: design and manufacture low-voltage switchgear in accordance with international standards and specifications for export and global applications.

Certification and testing: Ensure that products meet the safety and performance requirements of various countries through relevant certification and rigorous testing.

Through continuous innovation and development in these directions, low-voltage switchgear will be able to better meet the requirements of modern electrical systems for intelligence, reliability, environmental protection and high efficiency, so as to occupy a more favorable position in the future market competition.

VI. Summary

Low-voltage switchgear plays a vital role in modern electrical systems, and its importance is reflected in many aspects:

- The core of power distribution and control: Low-voltage switchgear is a key component of the power system, responsible for the distribution and control of power. It ensures that power can be transmitted to various electrical equipment in a stable and safe manner, ensuring the normal operation of electrical equipment.

- Ensure system safety and stability: The low-voltage switchgear integrates various protective devices such as circuit breakers, fuses, relays, etc. These protective devices can respond quickly to electrical faults (such as short circuit, overload, etc.) and cut off the fault circuit to prevent the expansion of accidents and ensure the safety and stability of the system.

- Intelligent and Digital Advancements: With the advancement of smart and digital technologies, low-voltage switchgear is increasingly becoming a vital component of smart grids. Through intelligent monitoring and control systems, IoT integration, and other technologies, these switchgear units can achieve remote monitoring and management capabilities, thereby improving operational efficiency while reducing maintenance costs.

- Improving energy efficiency and environmental protection: Low-voltage switchgear can optimize the use of electricity, reduce energy waste and reduce carbon emissions by integrating energy efficiency management system and using environmentally friendly materials, which is in line with the trend of green development.

- Reliability and long life: Using high quality, long life key components and advanced protection technology, the low-voltage switchgear can maintain stable operation under high load and complex electromagnetic environment, reduce downtime and maintenance costs, and improve the reliability and life of the system.

- Modular and miniaturized design: The modular and miniaturized design of the low-voltage switchgear not only improves the flexibility and scalability of the system, but also simplifies the installation and maintenance process, reduces the footprint and cost.

- Data analysis and predictive maintenance: Through big data analysis and machine learning technology, low-voltage switchgear can provide data support for equipment operation status and performance, realize predictive maintenance and fault prevention, and further improve the reliability and safety of the system.

- Adapt to diversification and customization needs: Low-voltage switchgear can provide customized solutions according to the special needs of different industries and customers, meet the requirements of specific application scenarios, improve user satisfaction and market competitiveness.

In conclusion, low-voltage switchgear plays an irreplaceable role in power systems. Through continuous technological innovation and development, these cabinets not only enhance the safety, reliability, and efficiency of power systems, but also adapt to future trends of intelligence, digitalization, and environmental protection, thereby driving the modernization and sustainable development of power infrastructure.